Black Box Thinking in the Healthcare and Aerospace Industries

Black Box Thinking in Aerospace and Healthcare

In the quest for progress and excellence, problem resolution serves as a critical cornerstone across industries. In both the healthcare and aerospace sectors, the approach to handling challenges can make all the difference in ensuring safety, innovation, and efficiency. Drawing insights from Matthew Syed's illuminating book "Black Box Thinking," we will delves into the distinct problem-resolution approaches (such as the Poke Yoke concept) and challenges they face in these industries, highlighting how embracing a culture of learning from mistakes can drive transformative change.

The Black Box Thinking Framework

Matthew Syed's "Black Box Thinking" advocates for a mindset that embraces failure and leverages it as a catalyst for growth. In the aviation industry, black boxes record flight data, aiding investigations into accidents and enabling continuous improvement. This culture of learning from mistakes allows the aerospace industry to make significant advancements in safety and design.

Healthcare: Challenges and Evolving Practices

In healthcare, problem resolution is of paramount importance as it directly impacts patient safety and care quality.

Historically, a fear of litigation and reputational damage hindered a transparent approach to addressing errors. However, in recent years the industry has been steadily shifting towards a more open culture of learning from mistakes, borrowing insights from other industries such as the aerospace black box concept. We see this everyday with our own NHS.

Aerospace: Embracing Failure to Soar Higher

The aerospace industry's proactive approach to problem resolution is a shining example of black-box thinking.

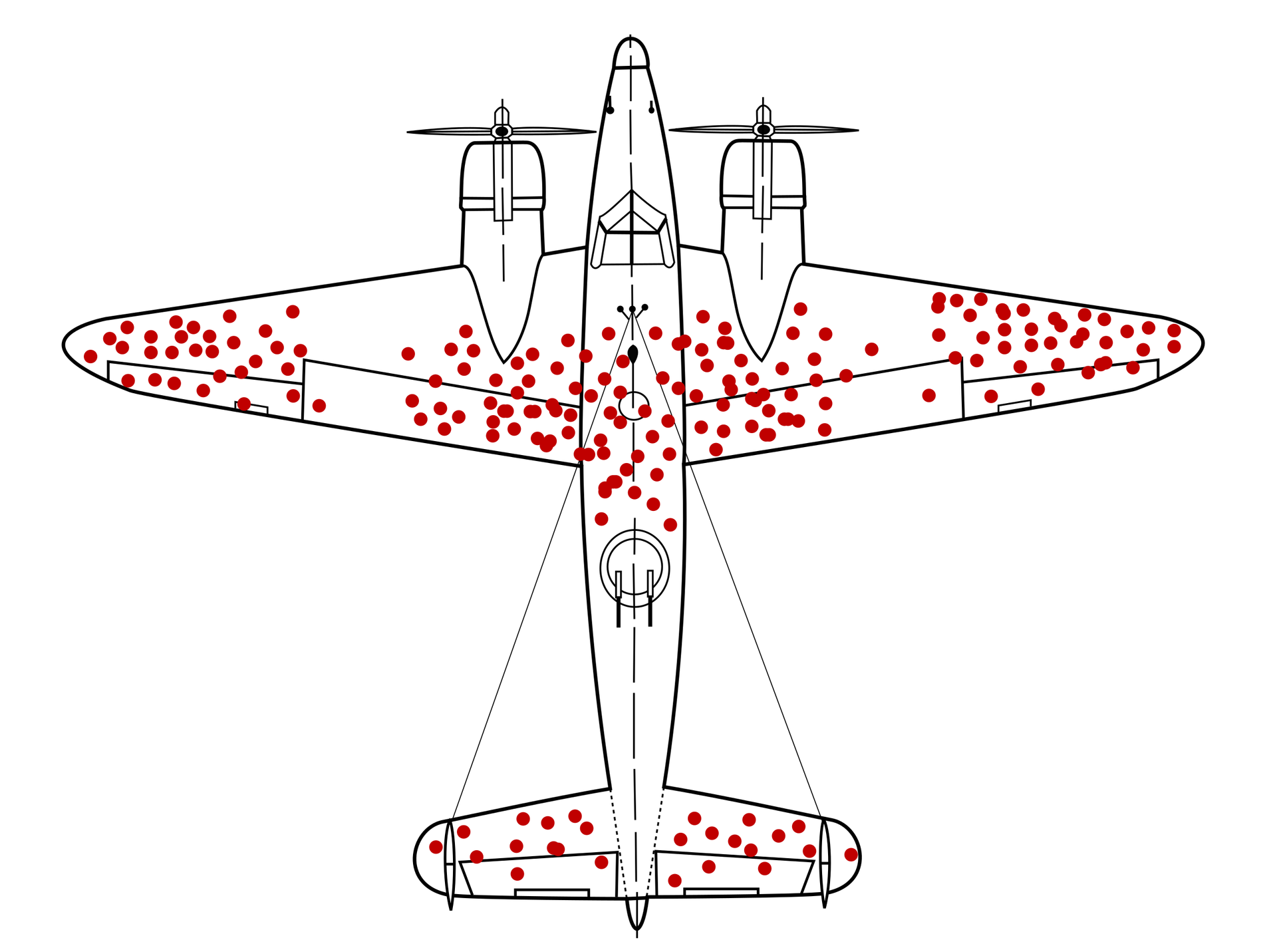

By thoroughly investigating accidents and near-misses and quality escapes, they unearth valuable data that drives innovation and safety improvements. This relentless pursuit of knowledge has led to remarkable advancements in aircraft design and pilot training. A great example is "Survivorship bias" (image below) and the returning planes of World War II and the approach developed by Abraham Wald and the Statistical Research Group (SRG).

For context, have a look at the image (Showing the visible bullet holes in a returning WWII fighter plane), which is then well explained in an excerpt from How Not To Be Wrong by Jordan Ellenberg.

"The officers saw an opportunity for efficiency; you can get the same protection with less armour if you concentrate the armour on the places with the greatest need, where the planes are getting hit the most. But exactly how much more armour belonged on those parts of the plane? That was the answer they came to Wald for. It wasn’t the answer they got." The armour, said Wald, doesn’t go where the bullet holes are. It goes where the bullet holes aren’t: on the engines. Wald’s insight was simply to ask: where are the missing holes? The ones that would have been all over the engine casing, if the damage had been spread equally all over the plane? Wald was pretty sure he knew. The missing bullet holes were on the missing planes. The reason planes were coming back with fewer hits to the engine is that planes that got hit in the engine weren’t coming back."

A fantastic example of how data analysis and insights impact historical real-world problems.

Healthcare Industry: Learning from Failure to Heal Better

While the healthcare industry is gradually adopting the principles of black-box thinking, challenges persist. The fear of malpractice litigation and a culture that discourages openness can hamper progress. Nevertheless, successful examples of medical institutions implementing transparency initiatives demonstrate the potential of black-box thinking in healthcare.

How to Embrace a Learning Culture

The key to successful problem resolution lies in fostering a learning culture that encourages open communication, sharing of insights, and continuous improvement:

Encouraging Reporting

Industries can promote a blame-free reporting culture where employees feel safe reporting errors or near-misses without fear of punitive measures.

Root Cause Analysis

Engaging in thorough root cause analysis allows organisations to identify the underlying factors contributing to problems and implement effective solutions.

Feedback Loops

Establishing feedback mechanisms enables organisations to track the impact of implemented solutions and refine approaches as needed. Think "how do we stop ourselves from reverting back to type?"

What Is Poka-Yoke?

A Simple Way to Prevent Errors Before They Happen

Poka-Yoke is a Japanese term that means “to avoid (yokeru) mistakes (poka)”. It’s a smart, simple design principle used to prevent human error at the source. Think of it as a failsafe that stops things going wrong before they have a chance to.

Originally developed in manufacturing, particularly in Toyota’s production system, Poka-Yoke is now used across many sectors; including healthcare and aerospace, to improve quality control, reduce waste, and protect both customers and employees from preventable errors.

Why Poka-Yoke Matters in High-Stakes Environments

From Checklists to Equipment Design – Small Tweaks, Big Impact

In the aerospace industry, checklists are sacred. In healthcare, surgical instruments are counted, labelled, and cross-verified to avoid being left inside patients. These aren’t just best practices, they’re classic examples of Poka-Yoke in action.

By making it hard to do the wrong thing, or even impossible, we drastically reduce the risk of harm. This approach aligns closely with Lean Six Sigma methodology, where the goal is always to remove variation and minimise the opportunity for defects.

Real-World Examples of Poka-Yoke

How Mistake-Proofing Shows Up in Daily Life

- Car gear lever locks that prevent you from switching into reverse accidentally

- Microwave ovens that don’t start until the door is closed

- Medication packaging with distinct shapes to prevent mix-ups

- Connectors and ports that only fit one way like plug sockets

These are small interventions, but they have big safety implications, especially when scaled.

How Can You Use Poka-Yoke in Your Organisation?

Actionable Steps to Get Started

Implementing Poka-Yoke doesn't have to be complex. Start by:

- Identifying high-risk errors – Where are mistakes likely to happen?

- Mapping the process – Visualise the steps using process analysis tools.

- Designing a safeguard – Introduce something simple that either prevents the mistake or alerts the user.

- Testing and refining – Use data and feedback to improve your solution.

Whether you're in healthcare, logistics, retail, or manufacturing, Poka-Yoke can be your first line of defence.

The Link Between Poka-Yoke and Black Box Thinking

Learning from Mistakes, Then Preventing Them

Black Box Thinking encourages us to view mistakes not as setbacks but as opportunities to learn. Poka-Yoke takes this a step further—by eliminating the mistake altogether. The synergy between these approaches lies in the mindset: we don’t hide errors, we design systems that make them harder to happen in the first place.

By using both philosophies together, organisations can not only respond better to failure, but actually stop it at the source of the problem.

FAQs About Poka-Yoke

What is Poka-Yoke?

Poka-Yoke is a method used to prevent mistakes by designing processes or tools that make it hard to get things wrong. It’s like putting up safety rails to stop people falling off the edge.

Poka-Yoke or Poke-Yoke?

While the term is often misheard or misspelt as "poke yoke", the correct spelling is "poka-yoke". It comes from Japanese "poka" meaning "inadvertent mistake" and "yokeru" meaning "to avoid", so together it means "mistake-proofing".

Where is Poke-Yoke used?

It’s used in manufacturing, healthcare, logistics, hospitality, and many other industries. Anywhere human error can cause problems and you can apply Lean Principles, Poka-Yoke can help.

What is the difference beteen Poke-Yoke and Quality control?

Quality control finds and fixes errors after they happen. Poke-Yoke prevents them from happening in the first place.

Is Poka-Yoke part of Lean Six Sigma?

Yes. It fits under the Lean Six Sigma umbrella as a practical tool for defect prevention, waste reduction, and process improvement.

Can small and medium businesses use Poka-Yoke?

Absolutely. You don’t need a big budget. Even simple labels, colour coding, or checklists can be powerful mistake-proofing tools. They just need to impact the source and not be able to be bypassed.

In the healthcare and aerospace industries, problem resolution plays a pivotal role in safety, quality, and innovation. Inspired by Matthew Syed's "Black Box Thinking," both sectors are moving towards a culture that learns from mistakes and embraces failures as stepping stones to improvement. While the aerospace industry has long championed this mindset, the healthcare sector is embarking on a path of transformation towards a similar approach. By nurturing open communication, conducting thorough analyses, and fostering a culture of learning, these industries are ushering in a new era of progress and safety.

If you’re looking to create safer, more efficient systems whether on the shop floor, in a hospital theatre, or at 30,000 feet, then Poka-Yoke and Black Box Thinking can give you the mindset and the methods to lead meaningful change.

Want help identifying opportunities for mistake-proofing in your organisation?

👉 Get in touch with VA Innovation to explore how we can support you.

Contact Us

Top Lean Six Sigma Reads: