Lean Training by VA Innovation

Transforming Processes, Elevating Profits: Your Lean Six Sigma Journey Starts Here

Transform Your Business with Lean Training

Are you looking to streamline your processes, reduce waste, and improve efficiency? Our Lean Training courses at VA Innovation are designed to help professionals and businesses optimise operations, enhance quality, and improve service delivery.

Lean Management is all about working smarter, not harder. It’s a proven methodology focusing on continuous improvement by eliminating unnecessary waste (MUDA), reducing cycle times, and increasing productivity. Whether you're in manufacturing, healthcare, finance, or service industries, Lean principles can revolutionise the way you work.

We are a UK Registered Learning Provider, UKPRN: 10093786, ensuring quality and credibility in all our training services.

What Lean Training Is It Recommended That Everyone Take?

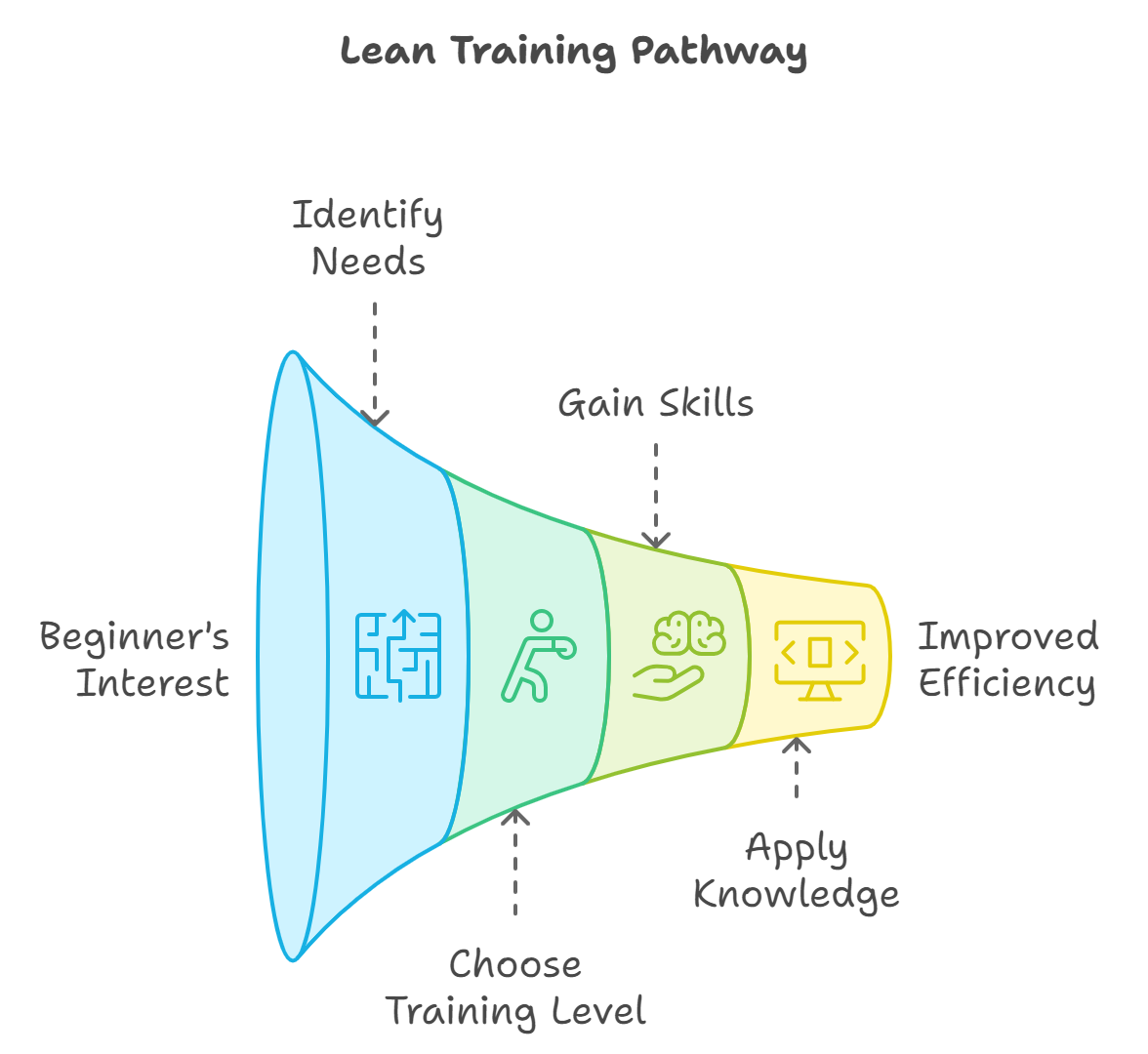

We’re often asked, "What Lean training should I take?" The world of Lean Six Sigma and continuous improvement can seem overwhelming, especially if you’re new to the terms. But don’t worry! We’re here to break it down for you in simple, easy-to-understand terms. Whether you’re an individual looking to improve your skillset or a business aiming to streamline your processes, Lean training can be a game-changer.

We’ll walk you through the different levels of Lean training and explain which ones are best suited for you or your business. By the end, you’ll have a clear idea of what training is right for you and why Lean Six Sigma principles are critical for improving efficiency.

What Is Lean Training?

Lean training teaches you how to identify and eliminate waste in processes, improving efficiency and productivity.

It’s widely used across industries to reduce costs, boost quality, and make operations run smoother.

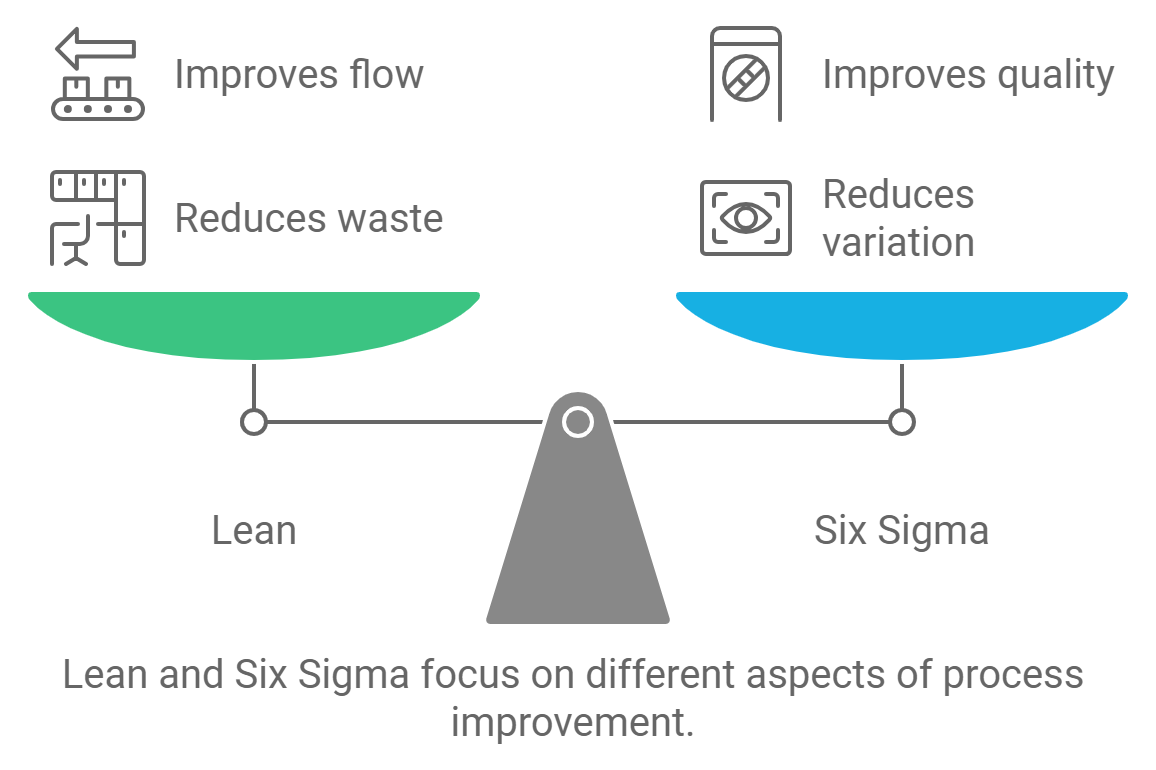

At the core of Lean training is Lean Six Sigma, a methodology that combines Lean practices (focused on waste reduction) and Six Sigma techniques (focused on improving process quality). By learning and applying Lean Six Sigma, you can help create a culture of continuous improvement in your workplace.

What are the Levels of Lean Six Sigma Training?

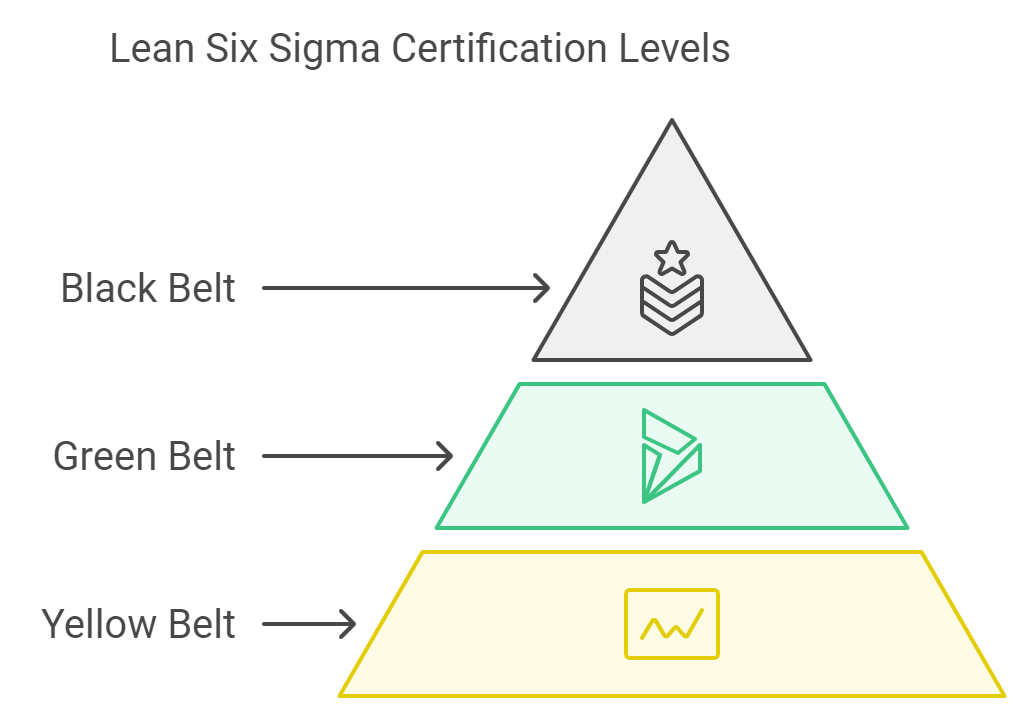

There are three key levels of Lean Six Sigma certification that are most common:

- White Belt

- Yellow Belt

- Green Belt

- Black Belt

Each level builds on the previous one, allowing you to gradually expand your knowledge and skill set.

For more in depth insight have a look at our information on the different belts!

Training, Certification or both?

Training and certification aren’t the same beast. The training side is all about learning the basics, getting your feet wet

White and Yellow Belt courses are all about basic training – they give you a solid foundation and introduce you to the key concepts.

Certification, on the other hand, is where the real commitment shows.You’re not just learning theory; you’re expected to demonstrate a solid grasp of the techniques and apply them in real-world settings

Green and Black Belt, are certifications where you’re expected to apply these principles in practice and prove your expertise through more rigorous assessment and a project. Certification is the badge that says you’ve truly earned your stripes.

Is Lean only for manufacturing?

No! While Lean originated in manufacturing, it is now widely used in healthcare, finance, service industries, and more. Any business that wants to improve efficiency can benefit from Lean Training.

How long do Lean Training courses take?

Our Lean Training courses range from 1-day intensive sessions to customised programs tailored to meet specific business needs.

What are the benefits of Lean Training?

Lean Training helps businesses:

- Reduce waste and inefficiencies

- Improve customer satisfaction

- Increase profitability

- Create a culture of continuous improvement

Do I need any prior knowledge to participate?

No prior experience is required! Our training is designed for beginners and professionals alike, with practical examples to help you apply what you learn immediately.

What is the difference between Lean and Lean Six Sigma?

Lean focuses on reducing waste and improving flow, while Six Sigma focuses on reducing variation and improving quality. When combined with Lean Six Sigma, they form a powerful methodology that improves both efficiency and quality. For more on the intricacies have a look at our blog "Lean vs. Six Sigma"

How long does it take to get Lean Six Sigma certified?

Yellow Belt training can take a few days but is uncertified, Green Belt typically lasts a few weeks into months due to the project work, and Black Belt programs may last several months even years, depending on the depth of the training and projects undertaken.

Is Lean Six Sigma certification worth it?

Yes! Lean Six Sigma certification is highly valued across industries and can open up career opportunities. It equips you with the skills to lead process improvement, reduce costs, and improve overall performance.

What industries use Lean Six Sigma?

Lean Six Sigma is used in various industries, including manufacturing, healthcare, IT, finance, and retail. Its principles are applicable anywhere there is a process to improve! Have a look at our case studies for some more in-depth insights!

Which Lean Training Is Best for You?

The right training depends on your role and goals:

- If you're just getting started or want to learn the basics, White Belt or Yellow Belt is a great choice.

- For those looking to actively lead improvement initiatives, Green Belt is more suited to your needs.

- If you're a leader aiming to drive large-scale change, then Green Belt or Black Belt is your go-to.

We recommend starting with the training level that aligns with your current responsibilities. However, even if you're a beginner, taking a Lean Six Sigma White belt or Yellow Belt training can give you the skills to identify inefficiencies and improve your organisations processes.

Benefits of Lean Six Sigma Training

Whether you choose White, Yellow or Green Belt, Lean Six Sigma training offers numerous benefits:

Efficiency and Waste Reduction

By applying Lean principles, you’ll learn how to streamline workflows, eliminate unnecessary tasks, and reduce waste – all leading to better productivity.

Data-Driven Decision Making

Lean Six Sigma focuses on using real data to identify problems and solutions. This means you won’t just guess at how to improve processes – you’ll have concrete evidence to back up your actions.

Empowerment and Engagement

Lean training encourages you to trust and empower employees. By involving them in the process improvement journey, you create a culture of engagement and innovation.

Why Choose VA Innovation for Lean Training?

We don’t just teach theory, we show you how to implement Lean in real-world scenarios. With decades of experience helping businesses improve performance, we provide practical, hands-on training that delivers results.

What sets us apart:

- Experienced Certified Lean Six Sigma consultants

- Practical, actionable training that you can utilise immediately

- Customised training solutions and plans to suit your business needs

Take the First Step Towards Lean Training Today!

No matter where you are in your Lean journey, there’s a training level for you. Whether you want to improve your personal skillset or drive change in your organisation, Lean Six Sigma training can help you achieve your goals. VA Innovation is here to support you every step of the way, from the initial training to ongoing coaching.

See what our clients think....

FAQs About VA Innovation

What is VA Innovation?

VA Innovation is a business consultancy specialising in Lean Six Sigma and process improvement. We help companies streamline operations, reduce costs, and improve efficiency.

What industries do you work with?

We work with a wide range of industries, including manufacturing, finance, healthcare, and service industries. Our Lean principles can be applied to any business looking to improve its processes.

Do you offer customised Lean Training?

Yes! We provide bespoke Lean Training tailored to your business needs, ensuring you get practical, actionable strategies that drive real results.

How do I contact VA Innovation?

You can visit our contact page here or reach out via email or phone to discuss how we can help your business.

If you are in search of specialised training tailored to your unique needs, please do not hesitate to reach out to us. We are here to assist you in finding the optimal solutions and training programs to elevate your skills and drive your organisational success. Connect with us to explore our diverse range of training offerings and discover how we can empower you and your team with the knowledge and expertise you seek.